Linear Guides in Automation: Applications and Future Trends

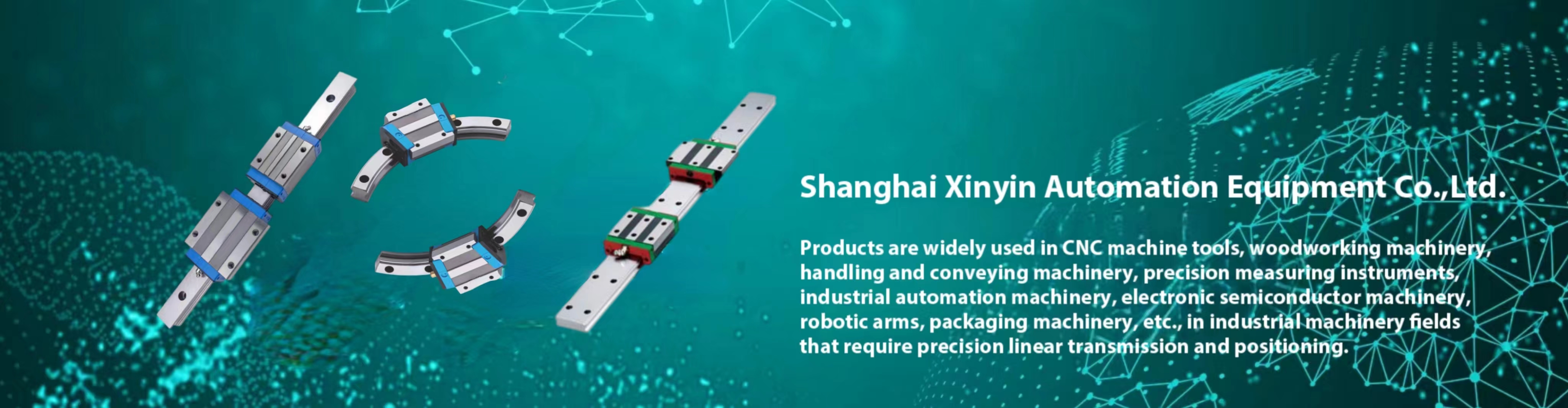

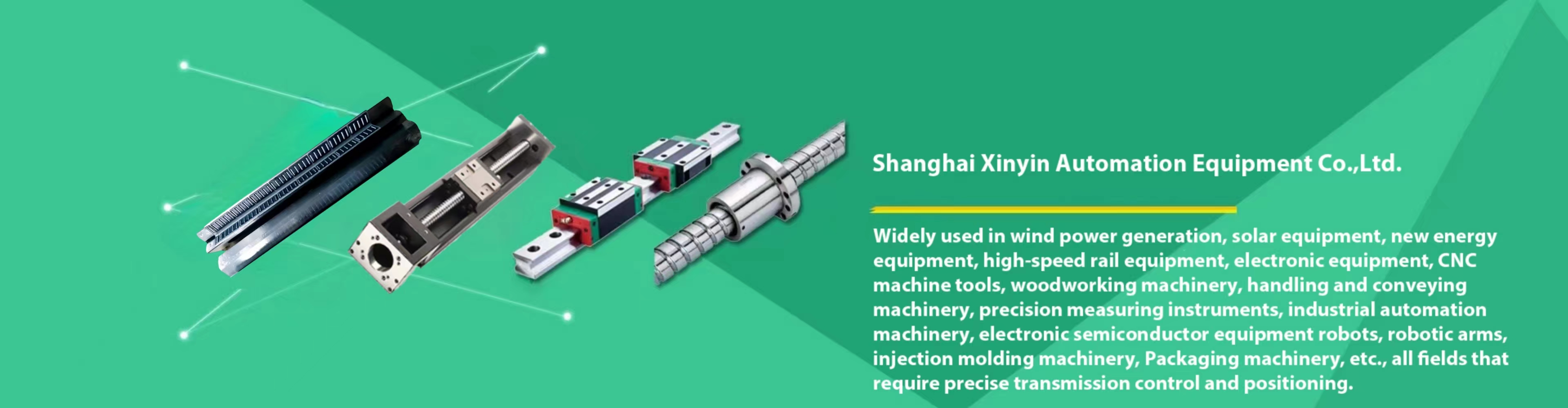

With the continuous development of industrial automation technologies, precise transmission and positioning systems have become core components in various automated devices. Linear guides, as a key component for achieving high-precision motion, are increasingly applied in modern manufacturing, robotics, CNC machining, and other industries. This article will explore the function, selection principles, and future trends of linear guides while introducing the innovations and contributions of Shanghai Xinyin Automation Equipment Co., Ltd. in this field.

1. Basic Principle and Role of Linear Guides

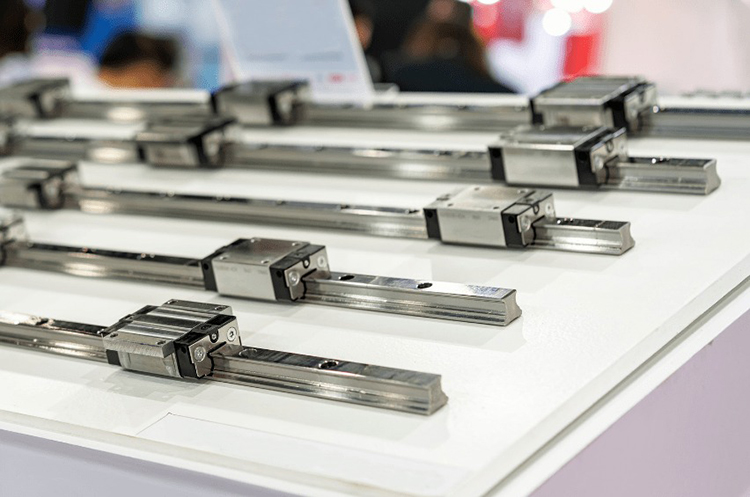

A linear guide (also known as a linear rail or slide) is a mechanical device used to support and guide linear motion. Its primary function is to provide stable support and ensure smooth movement of mechanical components along a straight path. Linear guides typically rely on rolling elements (such as ball bearings or roller bearings) that slide along the rail, reducing friction, improving efficiency, and achieving high-precision motion control.

In automation, linear guides are widely used in systems that require precise positioning and stable motion, such as CNC machines, industrial robots, and automated production lines. As one of the core components of precision transmission systems, linear guides significantly improve the operational accuracy and efficiency of equipment.

2. Classification and Selection of Linear Guides

Linear guides are available in various types, depending on the design and application requirements. Common classifications include:

Parallel Guides: Also known as square or rectangular guides, typically used for heavy loads and high-precision applications.

Curved Guides: Used in applications that require curved paths, such as robotic and packaging systems.

Ball Bearing Guides: These guides use ball bearings as rolling elements and are suitable for high-speed and high-precision transmission systems.

Linear Slides: Suitable for lighter loads but high-precision applications, such as 3D printers.

When selecting a linear guide, it is essential to consider factors such as load capacity, precision requirements, speed, and environmental conditions. Proper selection ensures the long-term stable operation of the guide system.

3. Applications of Linear Guides

Linear guides are used in multiple industries, particularly in areas where precision and stability are crucial. Here are some typical application scenarios:

CNC Machines: CNC machines require extremely precise motion control, and linear guides provide the stable and accurate support needed for these operations.

Industrial Robots: Linear guides ensure the precision and efficiency of robots in performing accurate movements.

Automated Production Lines: Linear guides enable high-speed, stable material handling, assembly, and inspection processes on automated production lines.

Packaging Machinery: In packaging systems, linear guides are used for precise positioning and smooth motion to ensure quick and accurate operations.

Medical Equipment: In medical devices, linear guides provide the precise motion control necessary for safe and accurate operations.

4. Shanghai Xinyin Automation Equipment Co., Ltd.'s Professional Solutions

Shanghai Xinyin Automation Equipment Co., Ltd., a leading linear guide manufacturer, is dedicated to providing high-quality automation components for various industries. The company's product range includes linear guides, ball screws, linear modules, and curved guides, which are widely used in CNC machines, robots, woodworking machinery, packaging equipment, and more.

Xinyin Automation not only represents the internationally renowned HIWIN brand of linear guides but also offers its own XYT series. These products, designed with high precision and quality control, meet the demands for high load, high precision, and high-speed applications across various industries. The company is committed to providing one-stop automation product solutions that help optimize equipment performance and enhance production efficiency.

5. Maintenance and Care of Linear Guides

To ensure the long-term stability and efficiency of linear guides, regular maintenance is essential. Xinyin Automation offers detailed maintenance guidelines to help extend the product's service life. Common maintenance tasks include:

Cleaning: Regularly clean the surface of the guides and rolling elements to remove dust and debris, preventing wear on the system.

Lubrication: Add lubricants, such as oil or grease, as needed to reduce friction and wear.

Inspection: Periodically check for wear on the guides and ensure that the rolling elements are intact. Replace any damaged parts promptly.

Environmental Control: In special environments (e.g., high humidity or temperature), additional protection is needed to avoid corrosion or thermal expansion, which may affect guide performance.

6. Future Trends of Linear Guides

With the advancement of smart manufacturing and Industry 4.0, linear guide technology is also continuously evolving. Future trends may include:

Higher Precision and Stability: As precision manufacturing technologies continue to improve, there will be higher demands for the accuracy and stability of linear guides. Future products will focus on error compensation and dynamic performance.

Smart Technology: Integrating sensors and IoT technology will allow for real-time monitoring of linear guides, providing fault alerts and maintenance recommendations to improve equipment reliability and reduce downtime.

Eco-friendly Materials: With growing awareness of environmental protection, future linear guides will be made from more eco-friendly materials to minimize their impact on the environment.

Lightweight Design: As industrial equipment demands higher efficiency, linear guides will move toward lighter designs without compromising load-bearing capacity or durability.

7. Conclusion

Linear guides play an indispensable role in the automation industry and are essential components in modern manufacturing and smart devices. From CNC machines to robots and automated production lines, the widespread use of linear guides has driven technological advancements and industry innovation.

As a professional linear guide manufacturer, Shanghai Xinyin Automation Equipment Co., Ltd. has built a strong reputation with years of industry experience and technical expertise. The company continues to provide high-quality automation products and customized solutions for various industries. Whether you need precise positioning in CNC machines or high-speed motion for industrial robots, Xinyin Automation’s products can offer stable and reliable support for your systems.

If you are looking for high-quality linear guides or customized automation solutions, feel free to contact Shanghai Xinyin Automation. We are committed to providing you with professional service and technical support.

- How Much Does a Rail Cost Per Meter? A Guide to Rail Selection and Price Influencing Factors

- What are the advantages of Shangyin heavy-duty ball screws

- What are the characteristics of Shangyin linear guideway

- What matters should be paid attention to when installing the ball screw?

- How to choose the type of ball

- Price of Steel-Inlaid Linear Guides and Their Applications in Industrial Machinery

- To ensure the normal operation of the silver guide rail, daily lubrication is very important! ! !

- What are the advantages of ball screw linear modules

- Arc Rack and Pinion Guide Rail Sliding Table: Key Component for Enhancing Precision and Efficiency in Industrial Automation

- Linear Guide Modules: Precision Linear Motion Solutions