Custom Non-Standard Ball Screws: Key Solutions for Precision Linear Motion

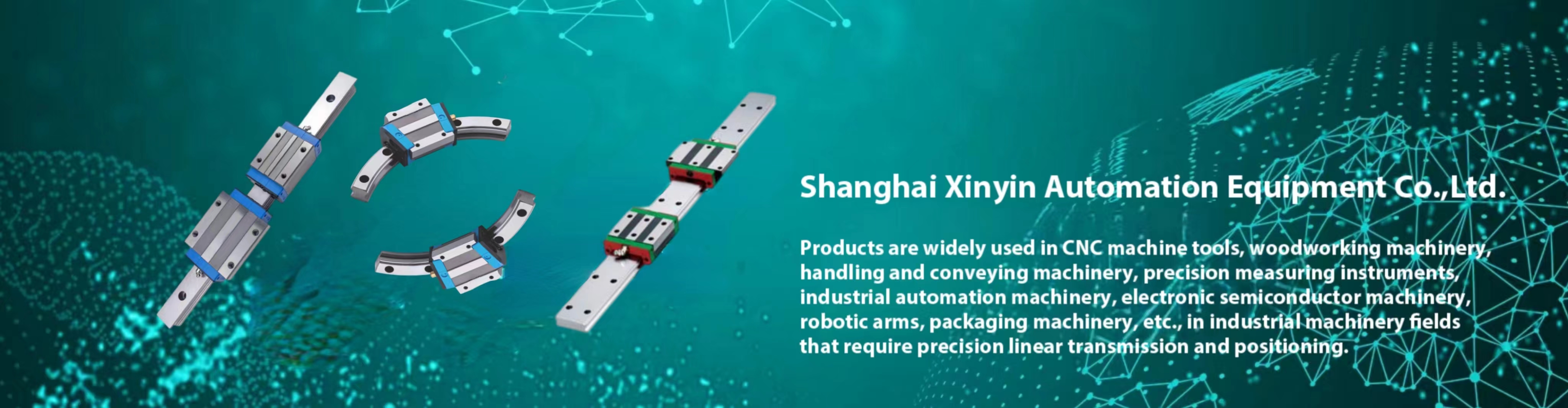

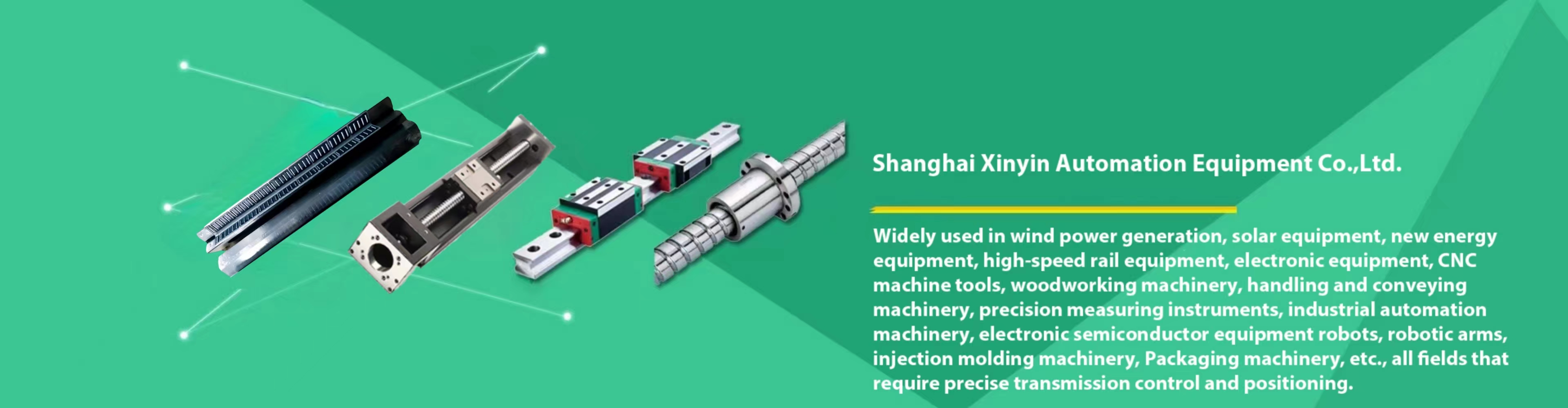

In the modern industrial automation sector, precision linear motion systems are of paramount importance. Shanghai Xinyin Automation Equipment Co., Ltd., a leading manufacturer of precision linear motion and positioning products, is dedicated to providing high-quality custom non-standard ball screws and other automation components. This article will explore the significance of custom non-standard ball screws and the advantages offered by Shanghai Xinyin in this field.

What Are Custom Non-Standard Ball Screws?

A ball screw is a mechanical component used to convert rotary motion into linear motion, and it is widely applied in CNC machines, robots, woodworking machinery, and other industrial automation equipment. Compared to standard ball screws, custom non-standard ball screws are specifically tailored to meet the unique requirements of customers, offering greater adaptability and precision to suit various complex or special operational environments.

Custom non-standard ball screws typically involve personalized adjustments in screw dimensions, ball sizes, material choices, lubrication methods, and installation types. Through precise design and manufacturing processes, custom non-standard ball screws provide reliable performance and extended service life in high-load, high-precision, and high-speed operations.

Advantages of Custom Non-Standard Ball Screws

Enhanced System Performance

Custom non-standard ball screws are designed to meet specific operational conditions such as special load, speed, and temperature requirements. This ensures improved system efficiency and eliminates issues when standard products fail to meet the demands.Increased Reliability and Stability

Custom-designed ball screws can maintain higher stability under extreme operational conditions, reducing failure rates due to excessive wear or malfunction, thus improving the reliability of the entire automation system.Space and Cost Savings

Custom ball screws can be optimized to fit specific application needs, saving space and reducing costs for other components. Through precise calculations, custom non-standard ball screws not only enhance the compactness of mechanical systems but also help customers lower overall production and maintenance costs.Improved Precision and Efficiency

Precision ball screws ensure highly accurate linear motion, enabling more precise positioning and control in high-precision machining processes. Whether used in CNC machines or robotics, they enhance both operational efficiency and accuracy.

Shanghai Xinyin Automation Equipment Co., Ltd.'s Custom Non-Standard Ball Screws

As a trusted supplier of automation equipment components, Shanghai Xinyin Automation Equipment Co., Ltd. offers several distinct advantages with its custom non-standard ball screws:

Custom Services

Shanghai Xinyin provides custom ball screw design and manufacturing services based on customer needs. Whether it's for special sizes, materials, or performance specifications, Shanghai Xinyin can offer the most suitable solutions for its customers.Wide Range of Applications

The company's products are widely used in CNC machines, woodworking machinery, industrial automation, robotics, packaging machinery, and other industries, meeting the diverse needs of clients across various fields.High-Quality Assurance

With high-quality products from the HIWIN Group and its own XYT brand, Shanghai Xinyin is committed to providing precision linear motion products, ensuring each component undergoes rigorous quality testing to guarantee long-term stable operation.Comprehensive Technical Support and After-Sales Service

Shanghai Xinyin offers complete technical support, from design to installation and post-sales maintenance, helping customers address any issues during usage and ensuring the efficient operation of their equipment.

Applications of Custom Non-Standard Ball Screws in Various Industries

CNC Machines

In CNC machines, custom non-standard ball screws provide precise positioning and high-accuracy machining, ensuring stable and efficient operation of each machine.Industrial Automation and Robotics

In automated production lines and robotic applications, custom non-standard ball screws offer efficient and precise motion control, improving production efficiency and reducing failure rates.Woodworking and Packaging Machinery

For woodworking and packaging machinery, custom non-standard ball screws meet high-speed and high-load operational demands, ensuring long-term stability and reliable performance.

Conclusion

Custom non-standard ball screws are essential components in modern industrial automation systems. Shanghai Xinyin Automation Equipment Co., Ltd. provides high-precision, custom-made ball screw solutions that help optimize the performance of mechanical systems and improve operational efficiency. Whether you are involved in CNC machining, industrial automation, or other fields, Xinyin Automation can offer tailored products and comprehensive services to support your business in achieving new milestones.

If you have any requirements for custom non-standard ball screws, please feel free to contact Shanghai Xinyin Automation Equipment Co., Ltd. We will provide you with professional consultation and solutions.

- What are the characteristics of Shangyin linear guideway

- Linear Guides in Automation: Applications and Future Trends

- What matters should be paid attention to when installing the ball screw?

- Arc Rack and Pinion Guide Rail Sliding Table: Key Component for Enhancing Precision and Efficiency in Industrial Automation

- Ring Rail Conveyor Systems: Pioneering Automation and Precision Transmission Technology

- Linear Guide Manufacturers: Key to Choosing High-Quality Automation Equipment Components

- How Much Does a Meter of Guide Rail Cost? Key Factors Influencing Guide Rail Prices

- Arc Rail Drive Methods and Application Guide

- Linear Guide Prices and Selection Guide: How to Choose the Right Guide for Your Needs

- How are linear guideways generally selected?