Ball Screw Customization According to Drawing – The Key to Enhancing Precision Transmission Efficiency

In the fields of industrial automation and precision machinery, ball screws have become an indispensable core component due to their high-efficiency and stable transmission performance. For many companies, selecting the right ball screw is crucial, especially when their products require specific sizes or functions. Shanghai Xinyin Automation Equipment Co., Ltd. offers professional ball screw customization according to drawing services to meet the diverse needs of customers.

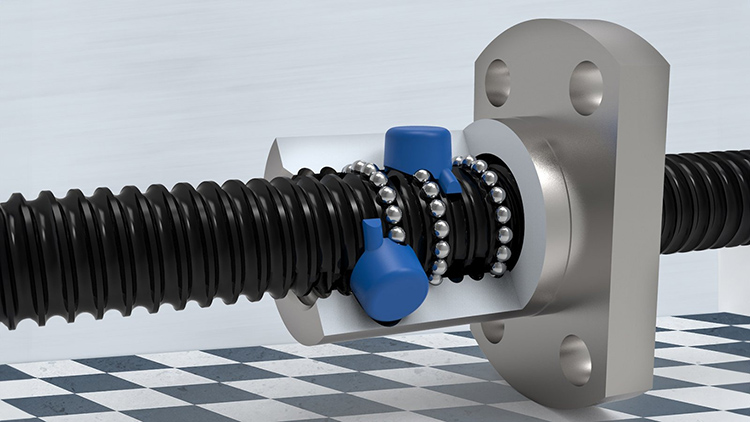

What is a Ball Screw?

A ball screw is a precision transmission component that converts rotary motion into linear motion. It is widely used in CNC machine tools, industrial automation equipment, woodworking machinery, packaging machinery, and more. The rolling balls between the screw and nut transmit power, and ball screws are known for their high efficiency, low friction, and long lifespan. Compared to traditional lead screws, ball screws can achieve a transmission efficiency of up to 90%, making them the preferred choice in modern automation systems.

Advantages of Ball Screw Customization According to Drawing

For many customers, standard ball screw products may not fully meet the specific needs of their equipment, particularly in terms of precision, size, or the requirements of certain working environments. Therefore, ball screw customization according to drawing offers a solution. Customers can provide drawings or design specifications, and Shanghai Xinyin Automation Equipment Co., Ltd. will tailor-make ball screws that meet those specific requirements.

1. Precision Matching to Meet Custom Needs

Every industry and every piece of equipment has different requirements. The specifications, size, and precision of a ball screw often need to be adjusted according to the actual situation. By customizing according to a drawing, customers can ensure that the ball screw fits perfectly with their equipment design, achieving optimal transmission performance.

2. Enhanced Equipment Performance and Stability

While standard ball screws can meet most needs, in some cases, they may not provide sufficient stability or performance. Customization allows for design optimization, improving the equipment's operating efficiency and stability, and reducing failure rates.

3. Shorter Production Cycles and Improved Production Efficiency

Customized production not only provides precise products according to customer needs but also shortens the development and manufacturing cycle. This helps customers quickly put their equipment into operation, improving overall production efficiency.

4. High-Precision Manufacturing to Ensure Consistent Quality

Shanghai Xinyin Automation Equipment Co., Ltd. boasts advanced production equipment and a professional technical team, ensuring that every step in the ball screw customization process is executed with precision. From material selection to manufacturing processes, every detail is carefully controlled to ensure high precision and consistent quality.

Shanghai Xinyin Automation Equipment Co., Ltd. – An Industry Leader in Customization Services

As a company specializing in the production and sale of precision linear motion and positioning products, Shanghai Xinyin Automation Equipment Co., Ltd. offers a range of automation components, including ball screws. Our products feature both the high-end HIWIN brand and our own XYT brand, meeting the diverse needs of various customers.

1. A Wide Range of Product Options

In addition to ball screws, Shanghai Xinyin also offers linear guides, linear modules, arcuate guides, and other precision automation components, which are widely used in CNC machine tools, woodworking machinery, industrial automation, robotics, packaging machinery, and more. All our products undergo strict quality testing to ensure their long-term, stable operation.

2. Leading Technology and Equipment

Shanghai Xinyin is equipped with state-of-the-art production technology and equipment, allowing for efficient and rapid customization. We not only provide standard products but also offer personalized customization services based on customers' drawings and technical requirements.

3. Comprehensive After-Sales Service

We understand that high-quality after-sales service is a key reason why customers choose us. Whether it's product installation, commissioning, or ongoing maintenance, Shanghai Xinyin provides timely and professional services to ensure the long-term, stable operation of the equipment.

Applications of Custom Ball Screws

Ball screws, as the core component of precision transmission systems, are widely used in the following fields:

CNC Machine Tools: In CNC machine tools, ball screws provide high precision and efficiency in linear motion, ensuring processing accuracy and production efficiency.

Woodworking Machinery: Ball screws in woodworking machinery ensure precise transmission and improve equipment stability and machining accuracy.

Industrial Automation: In automated production lines, ball screws are used to transmit power, enabling efficient and precise automation operations.

Robotics: In robotics, ball screws are used in the joint areas of robots to provide high-precision motion control.

Packaging Machinery: Ball screws help packaging machinery control various operations with precision, improving production efficiency and product quality.

Conclusion

Ball screws, as a crucial component of precision transmission systems, directly influence the overall performance of mechanical equipment. Through ball screw customization according to drawing services, Shanghai Xinyin Automation Equipment Co., Ltd. can provide tailored solutions based on customers' individual needs, enhancing equipment performance and stability. With years of industry experience, advanced production technology, and strict quality control, Shanghai Xinyin has gained a strong reputation for offering high-quality products and services to numerous customers.

If you need custom ball screws or want to learn more about our products, feel free to contact us. Shanghai Xinyin Automation Equipment Co., Ltd. is committed to providing professional services and high-quality products!

- Shanghai Xinyin Automation Equipment Co., Ltd. — Innovation-Driven, Precision Manufacturing

- Linear Motion Modules in Modern Industry: Applications and Importance

- Linear Guide Prices and Selection Guide: How to Choose the Right Guide for Your Needs

- What are the advantages of Shangyin heavy-duty ball screws

- Will ball screws and linear guides be replaced by linear modules?

- The reason why Shangyin linear guideway are widely used

- How to maintain plastic linear bearings?

- Choosing Affordable V-Guides: Advantages of Shanghai Xinyin Automation Equipment Co., Ltd.

- Linear Guides in Automation: Applications and Future Trends

- Arc Rail Price and Application Field Analysis