Applications and Importance of Linear Guides and Blocks: Key Components Driving Industrial Automation and Precision Equipment

In modern industry, linear guides and blocks are essential mechanical components widely used in various high-precision devices. Whether in CNC machine tools, woodworking machinery, automation systems, or precision measuring instruments and semiconductor devices, linear guides and blocks play a crucial role. This article explores the application fields of linear guides and blocks and their significance in industrial production and automation systems, helping you understand their role in modern machinery.

What is a Linear Guide Block?

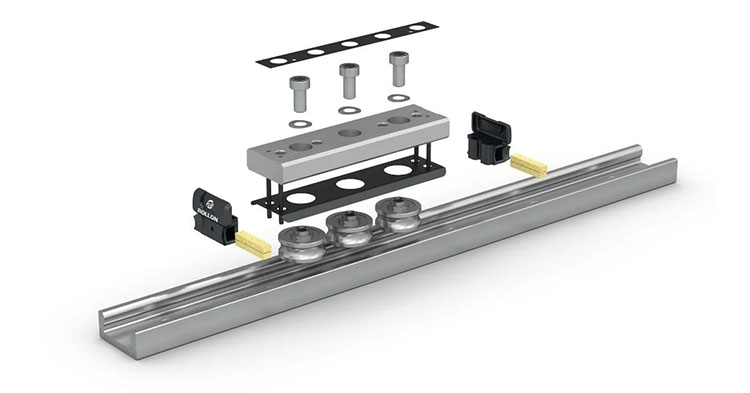

A linear guide block (also known as a linear slider or linear bearing) is a motion component used in conjunction with a guide rail system, enabling smooth linear movement along a track. It is typically made of high-precision steel or other materials and incorporates ball bearings or roller elements to provide stable and precise linear motion. The primary function of the linear guide block is to offer smooth linear guidance and positioning, ensuring that machinery can perform precise linear motion and transmission.

Main Application Areas of Linear Guides and Blocks

1. CNC Machine Tools

CNC machine tools are essential in modern manufacturing. Linear guides and blocks play a decisive role in these machines, particularly in precise positioning and high-speed motion. With high-precision linear guide systems, CNC machines can achieve superior processing accuracy and stability, meeting the manufacturing industry's dual demands for precision and efficiency.

2. Woodworking Machinery

In woodworking machinery, linear guides and blocks are widely used in wood cutting, sanding, carving, and other operations. These machines require precise linear motion to ensure fine wood processing. The smooth motion of linear guides enhances both the efficiency and precision of the machinery, ensuring consistent and accurate woodworking results.

3. Automation Equipment and Robotic Arms

The rapid development of automation equipment and robotics relies heavily on efficient linear guide systems. Linear guides and blocks in robotic arms and automation production lines significantly improve the accuracy and stability of the machinery, which is essential for increasing production efficiency and minimizing equipment failure.

4. Precision Measuring Instruments

Precision measuring instruments require extremely high motion accuracy and stability, and linear guides and blocks are commonly used in such devices. Whether in microscopes, testing machines, or other high-precision measuring instruments, linear guide blocks ensure precise motion, providing accurate measurement results.

5. Electronics and Semiconductor Industry

In the electronics and semiconductor manufacturing industry, linear guides and blocks are also crucial. These industries demand extreme precision and stability, and linear guides help ensure the precise installation and adjustment of small components. Whether in automated production lines or testing equipment for semiconductors, linear guides provide the necessary linear support.

6. Packaging Machinery

The efficient operation of packaging machinery relies on accurate linear guidance. Linear guides and blocks in packaging production lines enable precise positioning and stable operation, ensuring that the packaging process is efficient and reliable.

7. Conveyor Systems and Material Handling Machinery

In conveyor systems and material handling machinery, linear guides and blocks ensure that materials move smoothly and quickly along production lines. Their application improves the overall efficiency of the production line, facilitating fast and efficient movement of industrial products through different stages.

Key Technologies and Advantages of Linear Guide Blocks

The core technology of linear guide blocks lies in their high precision and durability, making them indispensable in many demanding industrial environments. Here are some key advantages of linear guide blocks:

High Precision Motion: Linear guide blocks provide precise linear motion, meeting the needs for high-precision positioning and transmission in various devices.

Stability and Durability: With ball or roller designs, linear guide blocks offer smooth motion and a long service life, even under heavy loads.

Adaptability to Various Work Environments: Different types of linear guides are designed to withstand various working conditions, including high temperatures, humidity, and contamination.

Low Friction Design: Optimized designs reduce friction, lower energy consumption, and increase work efficiency.

Vibration Resistance: Linear guide blocks effectively reduce vibrations in high-load or high-speed motion scenarios, improving equipment stability.

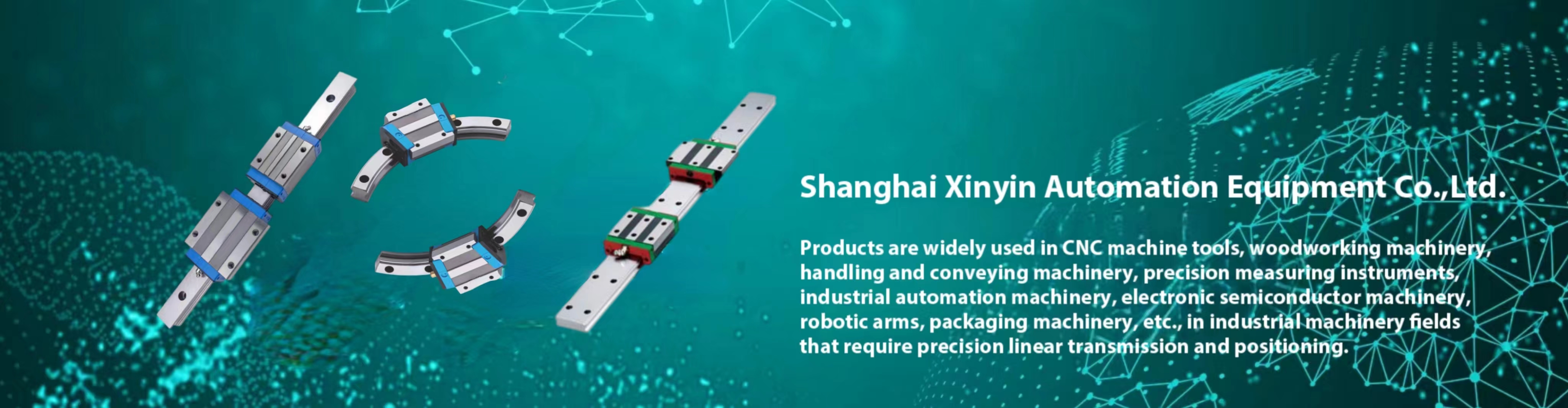

Linear Guides and Blocks from Shanghai Xinyin Automation Equipment Co., Ltd.

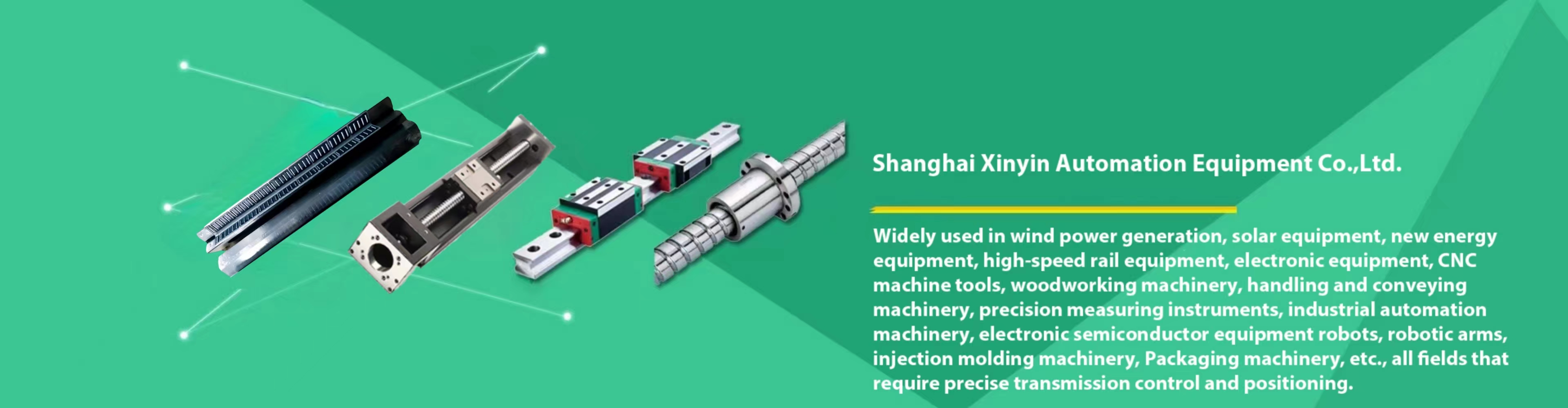

Shanghai Xinyin Automation Equipment Co., Ltd. is a professional supplier of industrial components, offering a wide range of linear guides and blocks that meet the needs of different industries and equipment. The products sold by the company include:

Linear Guides: Used in high-precision linear transmission systems, widely applied in CNC machine tools, automation equipment, and more.

Ball Screws: Provide efficient screw transmission, commonly used in machine tools, precision equipment, and other fields.

Linear Modules: Precision linear transmission components, suitable for various automation and precision control devices.

Miniature Roller Guides and Ceramic Guides: Ideal for specialized working environments, such as high temperatures, humidity, or precise motion requirements.

Conclusion

Linear guide blocks are essential components in modern industrial and automation systems, with wide applications and outstanding performance. Whether in CNC machine tools, precision measuring equipment, or in automation production lines and packaging machinery, linear guide blocks play a critical role in ensuring smooth and precise linear motion. Choosing the right linear guide products can significantly improve equipment motion accuracy and work efficiency. If you need high-quality linear guides and related components, Shanghai Xinyin Automation Equipment Co., Ltd. is your ideal partner.

For more product information or customized solutions, please visit Shanghai Xinyin Automation Equipment Co., Ltd.’s official website or contact our sales team.

- What are the advantages of Shangyin heavy-duty ball screws

- How much does one meter of linear guideway cost

- The reason why Shangyin linear guideway are widely used

- How Much Does a Guide Rail Cost per Meter? Shanghai Xinyin Automation Equipment Co., Ltd. Explains

- Linear Motion Modules in Modern Industry: Applications and Importance

- Arc Rail Drive Methods and Application Guide

- Linear Motion Modules: The Core Components for Enhanced Precision Transmission and Positioning

- What are the advantages of ball screw linear modules

- Shanghai Xinyin Automation Equipment Co., Ltd. — Innovation-Driven, Precision Manufacturing

- Linear Guides in Automation: Applications and Future Trends