Price of Steel-Inlaid Linear Guides and Their Applications in Industrial Machinery

With the continuous development of industrial automation and precision manufacturing technologies, various high-precision mechanical components have become indispensable in modern machinery. Among them, steel-inlaid linear guides play a crucial role in straight-line motion and positioning. These guides are widely used in CNC machine tools, woodworking machinery, precision measurement instruments, industrial automation equipment, and many other fields. This article will introduce the price of steel-inlaid linear guides, their applications in industrial fields, and how to choose the right steel-inlaid guide to help businesses enhance productivity and accuracy.

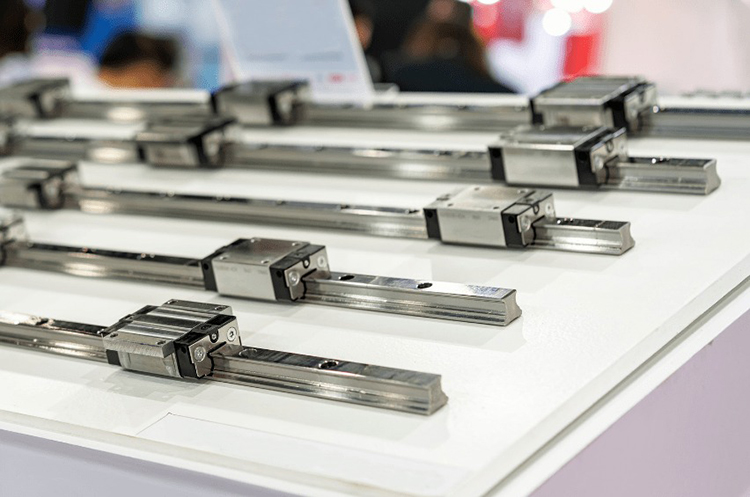

1. What Are Steel-Inlaid Linear Guides?

Steel-inlaid linear guides are linear motion guides made from steel, with an additional layer of specially engineered metal material inlaid on the surface to enhance wear resistance and stability. Their primary function is to guide mechanical parts along a fixed track for precise linear motion. Steel-inlaid guides offer high rigidity and durability, allowing them to withstand heavy loads, resist vibrations, and provide stable positioning accuracy, making them widely used in systems requiring high precision and reliability.

2. Key Features of Steel-Inlaid Linear Guides

High Load Capacity: Steel-inlaid linear guides can withstand significant loads due to their robust steel materials and inlay design, ensuring the stability and reliability of machinery over extended periods.

Low Friction Coefficient: The special surface design of the guide reduces friction with other moving parts, making the equipment run more smoothly and steadily.

Strong Wear Resistance: The wear-resistant properties of steel-inlaid guides allow them to operate for a long time in harsh working environments, reducing the frequency of replacement and lowering maintenance costs.

High Precision: Through precision machining, steel-inlaid guides offer high-accuracy positioning and linear motion, meeting the needs of high-precision machinery.

3. Factors Affecting the Price of Steel-Inlaid Linear Guides

The price of steel-inlaid linear guides is influenced by several factors. Understanding these factors can help purchasers make better decisions when selecting guides. The main factors include:

Material Selection: The material used in the manufacturing of steel-inlaid guides directly affects both performance and cost. High-strength steel, wear-resistant inlay materials, and the need for precision machining can all increase manufacturing costs, thereby raising the price.

Specifications and Sizes: The size and specifications of the guides are significant price factors. Custom sizes and special requirements typically involve additional processing and manufacturing costs, which can lead to higher prices.

Production Process: Different manufacturers use different production processes, which can influence the price of the guides. For example, some manufacturers may use high-precision equipment and advanced processes, leading to higher production costs and, consequently, a higher price.

Market Demand: Market demand for steel-inlaid guides can also influence their price. During times of high demand, prices may increase, while a drop in demand can result in price reductions.

4. Applications of Steel-Inlaid Linear Guides in Industrial Fields

Due to their excellent performance and stability, steel-inlaid linear guides are widely used across various industrial sectors. Here are some typical application scenarios:

CNC Machine Tools: CNC machines require high precision, and steel-inlaid linear guides provide stable linear motion and positioning, ensuring accuracy and efficiency in machining processes.

Woodworking Machinery: Steel-inlaid guides are commonly used in woodworking machinery for cutting, engraving, and other processes, ensuring precise operations and high-quality woodworking products.

Precision Measurement Instruments: Steel-inlaid guides help ensure stable movement in precision instruments, guaranteeing accurate measurement results.

Industrial Automation Machinery: Steel-inlaid linear guides are widely used in automated production lines, providing efficient, stable motion trajectories to support high-speed and high-precision automation tasks.

Electronic Semiconductor Machinery: In the electronics manufacturing industry, steel-inlaid guides ensure precise positioning and assembly of components, contributing to the quality and performance of electronic products.

Robotic Arms: In modern industry, robotic arms are used for automated handling and assembly tasks, and steel-inlaid guides ensure the accuracy and stability of robotic arm movements.

Packaging Machinery: Packaging machinery requires fast, precise positioning and transfer of products, and the use of steel-inlaid guides enhances efficiency and precision in the packaging process.

5. How to Choose the Right Steel-Inlaid Linear Guide

When selecting steel-inlaid guides, businesses need to consider several factors based on their specific application needs and working environments. Here are some tips for choosing the right guide:

Consider Load Requirements: Choose a steel-inlaid guide with sufficient load capacity based on the equipment's load requirements. For heavier workloads, guides with higher load-bearing capacity should be selected.

Understand the Working Environment: The temperature, humidity, and corrosiveness of the working environment affect the performance of the steel-inlaid guide. Be sure to choose guides suitable for various working conditions.

Choose the Right Size and Precision: Select the guide specifications according to the equipment's size and accuracy requirements to ensure the guide meets the operational needs of the system.

Evaluate Manufacturers and Brands: Choose reputable and experienced guide suppliers to ensure high-quality products and excellent after-sales service.

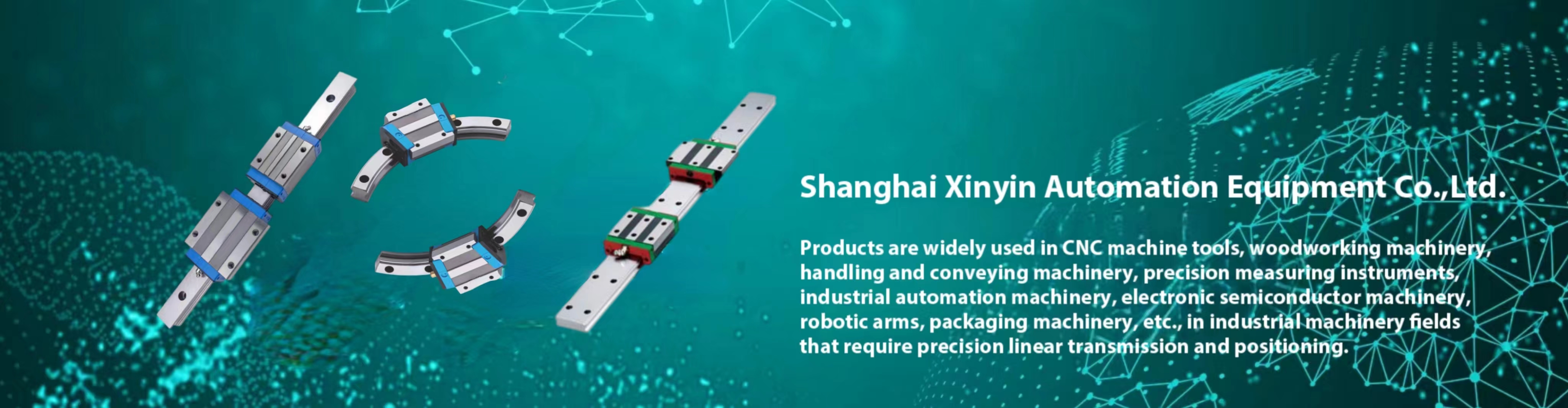

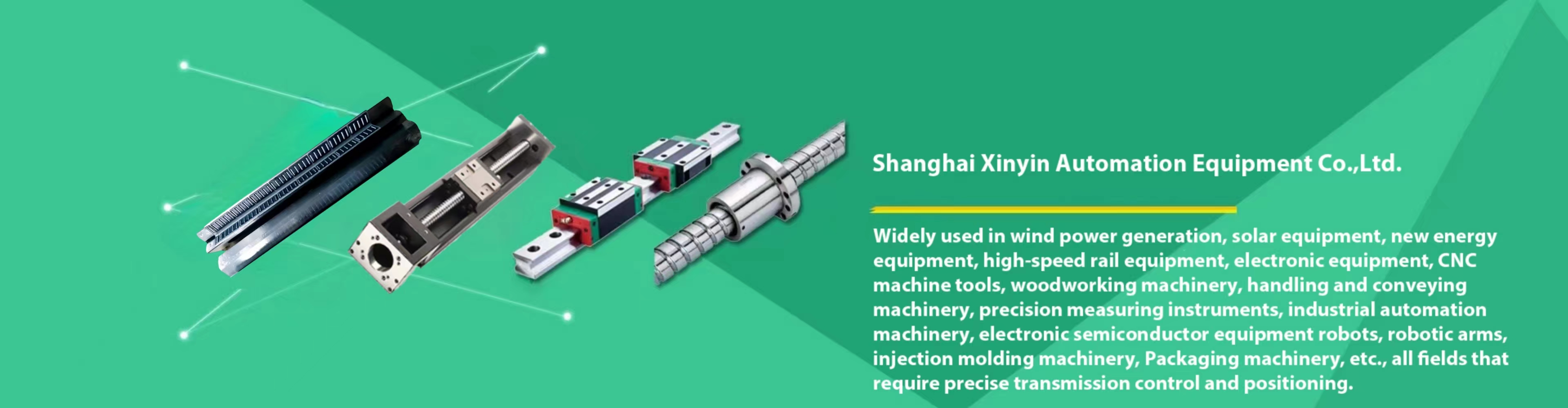

6. Advantages of Steel-Inlaid Linear Guides from Shanghai Xinyin Automation Equipment Co., Ltd.

Shanghai Xinyin Automation Equipment Co., Ltd. specializes in the research, development, and sales of high-precision linear guides and transmission components, offering high-quality steel-inlaid linear guides. The company's guide series includes linear guides, ball screws, linear modules, curved guides, and more, which are widely used in CNC machine tools, woodworking machinery, precision measurement instruments, industrial automation equipment, and other fields. Xinyin Automation Equipment’s products have earned a good reputation in the industry due to their excellent performance, competitive pricing, and superior customer service.

By choosing steel-inlaid linear guides from Shanghai Xinyin Automation Equipment Co., Ltd., businesses can benefit from high-precision, high-load-bearing capacity, and long-lasting products, helping to improve operational efficiency and equipment stability.

7. Conclusion

Steel-inlaid linear guides are crucial components in modern machinery, and their prices are influenced by multiple factors. When selecting steel-inlaid guides, businesses should consider factors such as load requirements, working environment, size precision, and more. Additionally, choosing a reputable supplier, such as Shanghai Xinyin Automation Equipment Co., Ltd., ensures high-quality products and excellent after-sales service, contributing to the overall performance and productivity of industrial equipment.

If you are looking for high-quality steel-inlaid linear guides, feel free to contact Shanghai Xinyin Automation Equipment Co., Ltd., and we will provide you with the most suitable solutions.

- What matters should be paid attention to when installing the ball screw?

- How much does one meter of linear guideway cost

- Ring Rail Conveyor Systems: Pioneering Automation and Precision Transmission Technology

- Applications and Importance of Linear Guides and Blocks: Key Components Driving Industrial Automation and Precision Equipment

- Linear Guide Prices and Selection Guide: How to Choose the Right Guide for Your Needs

- How to maintain plastic linear bearings?

- Shanghai Xinyin Automation Equipment Co., Ltd. — Innovation-Driven, Precision Manufacturing

- What are the advantages of ball screw linear modules

- Linear Motion Modules: The Core Components for Enhanced Precision Transmission and Positioning

- How are linear guideways generally selected?