How Much Does a Meter of Guide Rail Cost? Key Factors Influencing Guide Rail Prices

Guide rails are essential precision components in industrial machinery, widely used in applications such as CNC machine tools, automation production lines, packaging machinery, and more. When purchasing guide rails, many customers often ask, "How much does a meter of guide rail cost?" While the specific price can vary depending on the product and application, the cost of guide rails is influenced by several factors. Understanding these factors will help you make a more informed purchasing decision.

This article will explore the main factors that affect the price of guide rails and provide you with key considerations when selecting the right guide rail for your needs.

Key Factors Affecting Guide Rail Prices

1. Material of the Guide Rail

The material used for the guide rail is one of the most significant factors influencing its price. Common materials include:

Steel Guide Rails: These are the most common type, widely used in standard industrial equipment. Steel guide rails are typically priced more reasonably.

Cast Iron Guide Rails: Cast iron offers better vibration damping, wear resistance, and higher load-bearing capacity, which makes cast iron guide rails more expensive than standard steel ones.

Ceramic Guide Rails: Ceramic guide rails are ideal for high-temperature, corrosive environments, and are priced higher due to their specialized properties.

High-Temperature Guide Rails: These are designed to perform in high-temperature environments and are typically more expensive due to the complex production process required.

2. Type of Guide Rail

The type of guide rail also directly affects its price. Different guide rail types are suitable for different application scenarios, and their design and function differences make them priced differently:

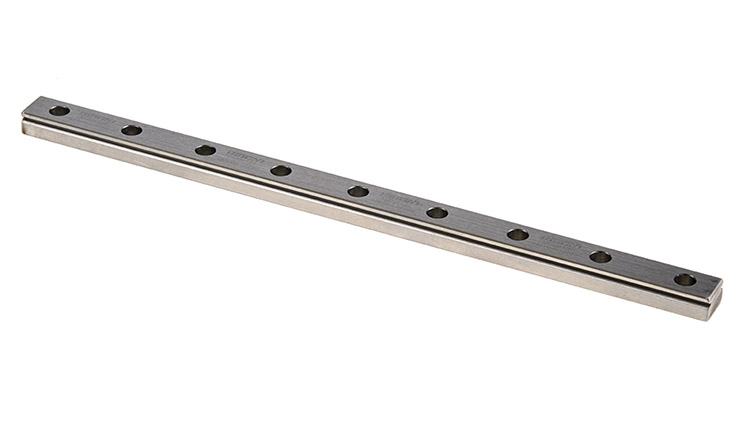

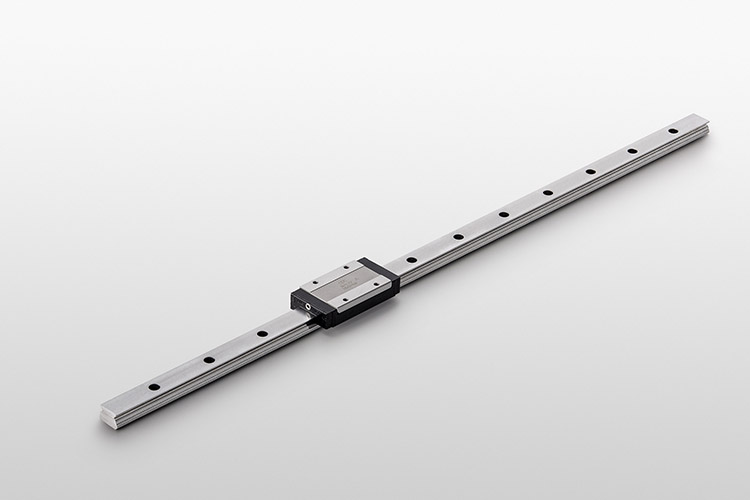

Linear Guide Rails: These are the most common type, used in a wide range of precision machinery. Linear guide rails are generally more cost-effective.

Ball Bearing Guide Rails: These guide rails use rolling balls to reduce friction, increasing lifespan and precision, so their price tends to be higher than traditional sliding guide rails.

Arc and Cross Roller Guide Rails: These are used in specialized curved or crossed motion systems, and their complex design results in higher prices compared to standard linear guide rails.

Miniature Guide Rails: Used in equipment where space is limited and precise movement is required, miniature guide rails are usually more expensive due to their high precision and specialized manufacturing process.

3. Precision and Performance Requirements

The precision and performance required for the guide rail directly affect its manufacturing complexity and cost. High-precision guide rails typically require more advanced processing and stricter quality control, which increases their cost. For example, guide rails used in CNC machine tools or precision measurement equipment require higher precision to ensure system stability and accuracy. In contrast, guide rails with lower precision requirements for more general applications tend to be more affordable.

4. Manufacturing Process and Brand

The manufacturing process and brand also influence the price of guide rails. Well-known brands typically use more stringent manufacturing processes and higher-quality materials, ensuring longer product lifespans and higher reliability, but at a higher price. On the other hand, non-branded or low-cost guide rails may be cheaper but could compromise on quality and stability. Therefore, when selecting guide rails, it is important to consider not just the price, but also the reputation of the brand and the product's long-term performance.

5. Customization Requirements

In some specialized applications, standard guide rails may not meet the requirements, and custom guide rails are necessary. Custom guide rails are typically produced based on the specific needs of the customer (such as size, material, load-bearing capacity, etc.), making them more expensive. Custom guide rails not only meet specific application requirements but also provide higher efficiency and reliability.

How to Choose the Right Guide Rail?

After understanding the main factors that affect the price of guide rails, choosing the right guide rail should not just focus on price but also on your specific application needs. Here are some tips for selecting guide rails:

Define the Application Scenario and Requirements

The first step in selecting the right guide rail is understanding the type of machinery and working environment in which it will be used. Different types of guide rails are suitable for different industrial applications, such as CNC machine tools, automation equipment, robots, packaging machinery, and more. Ensure you choose a guide rail that meets your precision, load-bearing, and environmental requirements.Evaluate Performance Requirements

Based on the operational needs of your equipment, determine the precision grade, wear resistance, corrosion resistance, and other performance requirements for the guide rail. For example, if your equipment operates in a high-temperature or corrosive environment, choosing high-temperature or corrosion-resistant guide rails would be a prudent decision.Consider Brand and After-Sales Service

Choosing a reputable guide rail brand generally ensures better product quality and after-sales service. While well-known brands may have a higher initial price, they can save you maintenance and replacement costs in the long run. Look for manufacturers that provide long-term technical support and warranties to ensure the stable performance of your guide rails over time.Balance Price and Performance

When selecting guide rails, consider not only the price but also the value they offer. Higher-quality guide rails may have a higher upfront cost but can reduce long-term maintenance costs and provide longer operational lifespans, thus offering better value for money.

Guide Rail Solutions from Shanghai Xinyin Automation Equipment Co., Ltd.

As a professional supplier of guide rails and precision transmission systems, Shanghai Xinyin Automation Equipment Co., Ltd. offers a wide range of high-quality guide rail products to meet the needs of various industrial fields. Our product range includes linear guide rails, ball screws, miniature guide rails, high-temperature guide rails, and more, widely used in CNC machine tools, woodworking machinery, automation production lines, precision measurement instruments, and semiconductor equipment.

We are committed to providing our customers with:

Quality Assurance: Our guide rails are made from high-quality materials and manufactured with advanced processes to ensure high precision and durability.

Comprehensive Customization Services: We provide tailored solutions based on your specific requirements, ensuring that the products meet your unique application needs.

Competitive Pricing: We offer reasonable prices based on market demand and production scale, ensuring the best balance between price and quality.

Professional After-Sales Service: Our experienced team offers technical support to ensure that your guide rails perform reliably over the long term.

Conclusion

When selecting guide rails, understanding the factors that influence the price, such as material, type, precision, and brand, can help you make an informed decision. In addition to price, it’s important to consider the material, design, performance requirements, and brand reputation to ensure that the guide rail meets your needs and operates efficiently over time.

If you are looking for high-quality guide rail products, feel free to contact Shanghai Xinyin Automation Equipment Co., Ltd. We will provide customized guide rail solutions based on your specific needs to help you improve equipment efficiency and reduce operational costs.

- Linear Motion Modules in Modern Industry: Applications and Importance

- Arc Rail Price and Application Field Analysis

- Linear Guides in Automation: Applications and Future Trends

- Applications and Importance of Linear Guides and Blocks: Key Components Driving Industrial Automation and Precision Equipment

- How are linear guideways generally selected?

- What matters should be paid attention to when installing the ball screw?

- Linear Guide Prices and Selection Guide: How to Choose the Right Guide for Your Needs

- To ensure the normal operation of the silver guide rail, daily lubrication is very important! ! !

- Ball Screw Customization According to Drawing – The Key to Enhancing Precision Transmission Efficiency

- Linear Guide Manufacturers: Key to Choosing High-Quality Automation Equipment Components