How Much Does a Rail Cost Per Meter? A Guide to Rail Selection and Price Influencing Factors

In modern automation, rails are essential components widely used in various mechanical devices, ensuring accuracy, stability, and efficiency. Whether in CNC machines, packaging machinery, or automation production lines, the quality of rails directly impacts the performance of the equipment. So, how much does a rail cost per meter? Apart from the price factor, what key aspects should be considered when selecting a rail? This article will explain these questions in detail and provide useful guidance for making informed choices.

1. Factors Affecting Rail Prices

The question of how much a rail costs per meter doesn't have a fixed answer because rail prices depend on various factors. Understanding these factors can help you make a more rational decision.

Material and Craftsmanship: Different rail materials come with different price points. Common materials include steel, aluminum alloy, and ceramics. Ceramic rails and high-temperature rails typically use specialized materials, making them more expensive. In contrast, standard steel linear rails are more affordable due to mature manufacturing processes.

Rail Type and Functionality: Rails come in various types based on the application. Regular linear rails and ball screws are typically used in general machinery, and their prices are generally more reasonable. However, rails designed for precise equipment, high loads, or specific functions (e.g., high-temperature or corrosion-resistant) are more expensive.

Accuracy Requirements: Equipment that demands higher precision and smoother operation requires more accurate rails. These rails usually come at a higher cost due to the more refined manufacturing processes.

Size and Load Capacity: Larger rails with higher load capacities are naturally more expensive. If your equipment requires larger rails to handle heavier loads, the price will increase accordingly.

2. Common Rail Types and Applications

Rails serve many different applications, and each type is suited to specific scenarios. Understanding the characteristics and application fields of each rail type will help you select the most suitable one for your needs.

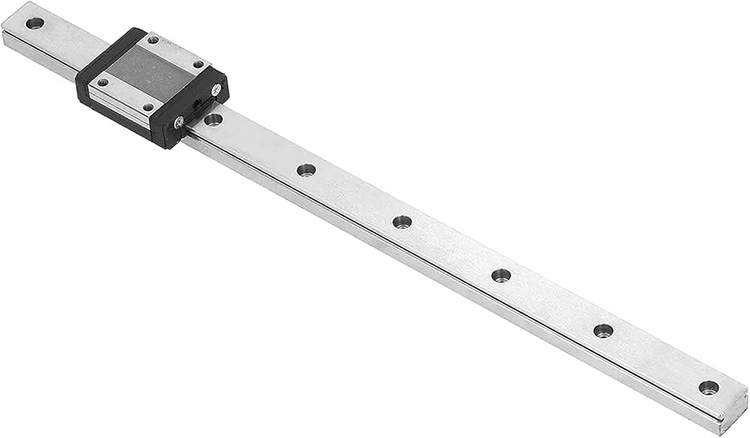

Linear Rails: This is the most common type, widely used in equipment requiring high-precision linear motion, such as CNC machines, industrial automation devices, and precision instruments. Linear rails generally offer a good balance between price and performance, making them suitable for most industrial applications.

Ball Screws: Ball screw rails are used for precision motion control and are common in high-precision positioning systems and automated devices. Due to their high efficiency and accuracy, ball screw rails tend to be more expensive than standard linear rails.

Curved and Crossed Roller Rails: These are suitable for applications requiring curved or multidirectional smooth motion, such as specialized robotic systems or custom workbenches. Due to the more complex design and manufacturing processes, the price of these rails is generally higher.

High-Temperature and Ceramic Rails: These rails are designed for specialized working environments such as high-temperature, high-pressure, or corrosive conditions. Due to the specialized materials and performance requirements, ceramic and high-temperature rails are typically more expensive.

Micro Rails: These are used in compact devices with limited space, such as precision instruments or micro-robotics. Micro rails generally require high precision, and often need to be custom-made or specially processed.

3. How to Choose the Right Rail?

When selecting a rail, it's essential to consider not only the price but also the specific requirements of your equipment and its operating environment. Here are a few factors to help guide your decision:

Application Type: Different devices have different rail requirements. For high-precision, high-speed equipment (such as CNC machines and precision measurement devices), high-precision rails should be chosen. For heavier equipment (such as conveyors or heavy-duty machines), rails with higher load capacity are preferable.

Operating Environment: The environment in which the rail will operate significantly influences its selection. For high-temperature or high-humidity environments, standard steel rails may not be suitable. In such cases, high-temperature or corrosion-resistant rails should be considered.

Space Constraints: If the application involves limited space, micro rails may be the only option. Micro rails are used in scenarios requiring high precision and compact designs, such as small automation devices and precision instruments.

Budget: The cost of rails varies greatly based on the type and function. Standard linear rails are typically cost-effective and offer excellent performance for most applications. However, for equipment with extremely high precision requirements, you may need to consider more expensive options such as high-precision rails.

4. Shanghai Xinyin Automation Equipment Co., Ltd. and Its Rail Products

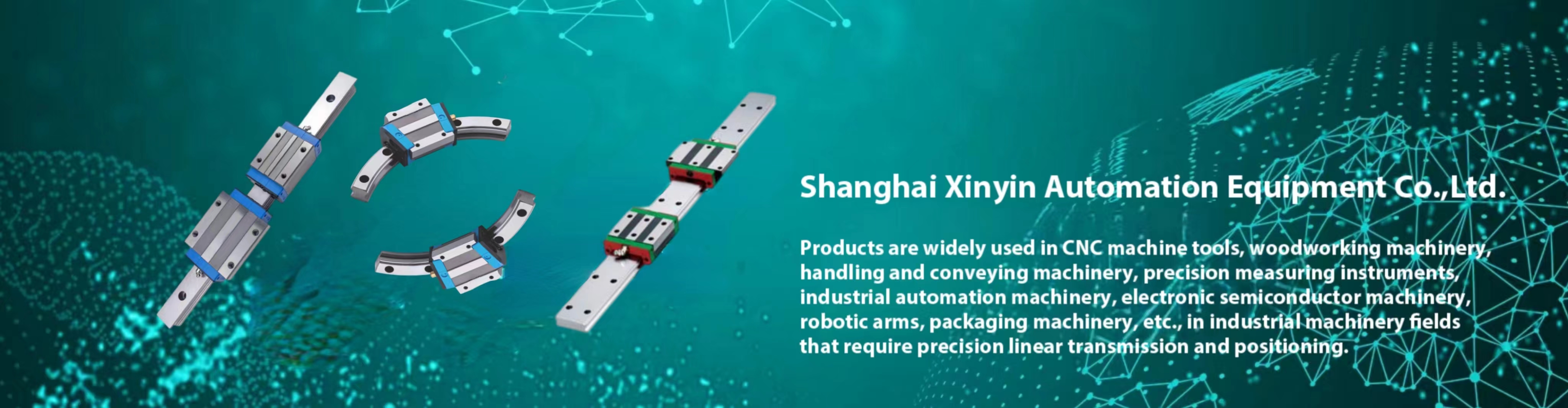

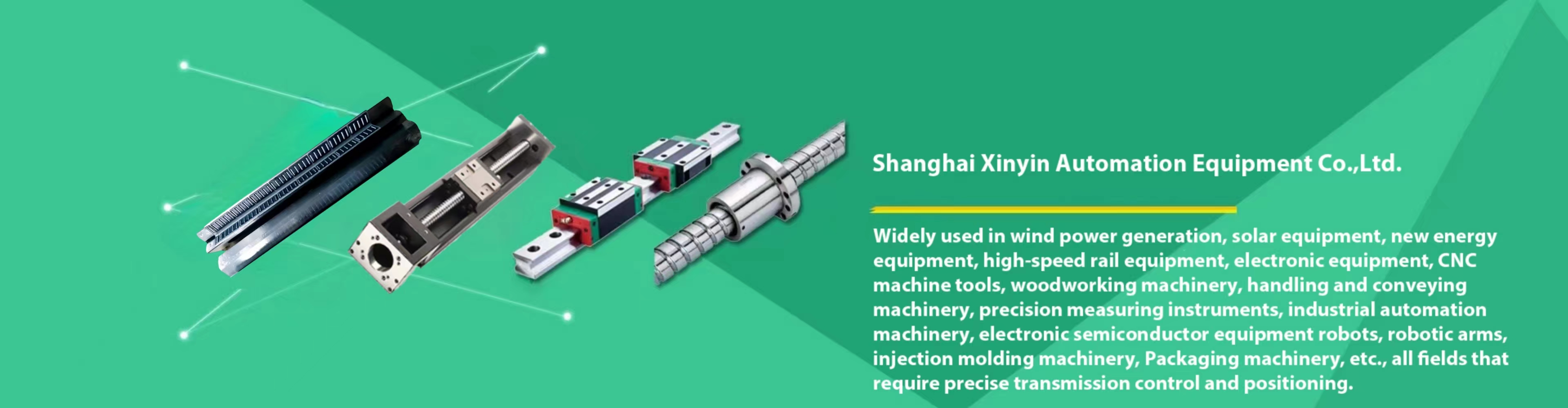

When selecting rails, it's also crucial to find a reliable supplier. Shanghai Xinyin Automation Equipment Co., Ltd., a professional supplier specializing in rail systems, offers a wide range of rail products, including linear rails, ball screws, micro rails, and more. These products are widely used in CNC machines, automation devices, precision instruments, and many other fields.

The rail products we offer are designed to provide high precision and stability, and we can also provide customized solutions based on customer needs. Our goal is to help customers solve precision transmission and positioning problems in various industries.

5. Rail Maintenance and Care

Even with the right rail choice, regular maintenance and care are crucial to ensure long-term reliability. Common rail maintenance practices include:

Lubrication: Regular lubrication reduces friction and extends the lifespan of the rail.

Cleaning and Inspection: Regularly clean the rails to remove dust and debris that could affect motion accuracy. Inspect the rails for wear and tear to ensure they continue to function optimally.

Installation Checks: Proper installation is critical to rail performance. Ensure the rails are installed accurately to avoid misalignment, which can impact the overall performance of the equipment.

Conclusion

After understanding how much a rail costs per meter and the factors that influence the price, it’s important to focus on selecting the right rail for your specific needs. By evaluating your equipment's requirements, environmental conditions, and budget, you can make a more informed choice. Regular maintenance and care also play a significant role in ensuring the long-term performance of your rail systems.

For more information on rail products or technical support, it is recommended to consult with professional suppliers who can offer precise advice and solutions tailored to your specific needs.

- Price of Steel-Inlaid Linear Guides and Their Applications in Industrial Machinery

- How to identify the authenticity of ball screws

- Customized Machine Tool Guide Price and Its Application Areas

- Arc Rail Price and Application Field Analysis

- Custom Non-Standard Ball Screws: Key Solutions for Precision Linear Motion

- Linear Motion Modules in Modern Industry: Applications and Importance

- Ring Rail Conveyor Systems: Pioneering Automation and Precision Transmission Technology

- Custom Non-Standard Guide Rails: The Key to Enhancing Precision Motion and Positioning in Industrial Applications

- Linear Motion Modules: The Core Components for Enhanced Precision Transmission and Positioning

- Ball Screw Customization According to Drawing – The Key to Enhancing Precision Transmission Efficiency