Linear Guide Prices and Selection Guide: How to Choose the Right Guide for Your Needs

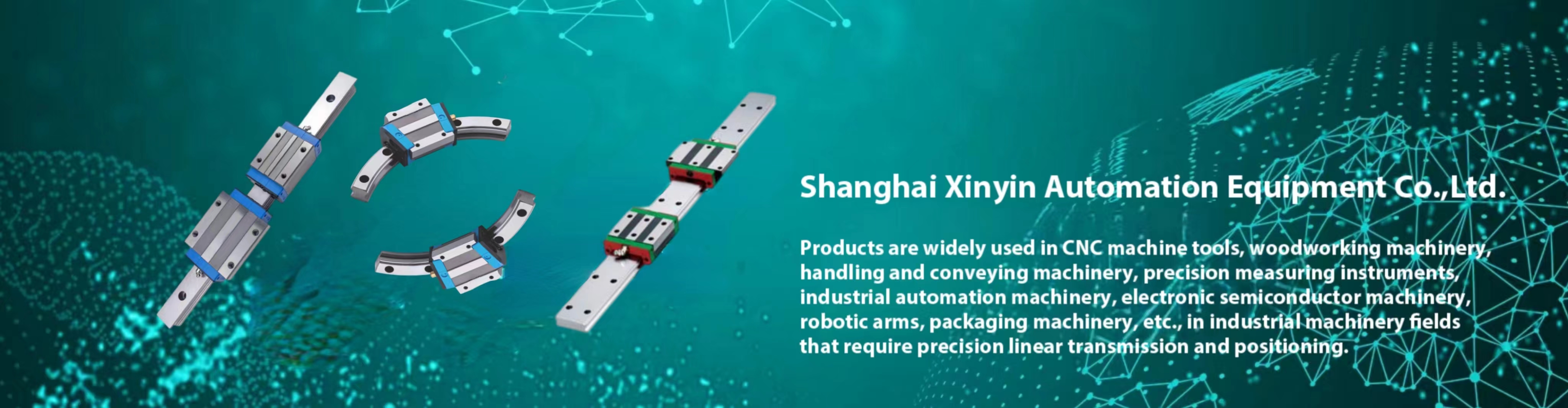

In modern industry, linear guides are a crucial component for precise motion transmission and positioning, widely used in CNC machines, automation equipment, packaging machinery, electronics manufacturing, and many other fields. Choosing the right guide not only improves equipment accuracy and efficiency but also extends the lifespan of the machinery. So, what is the general price of linear guides? How do you select the right guide for your needs? This article will help answer these questions.

1. Types of Linear Guides and Their Applications

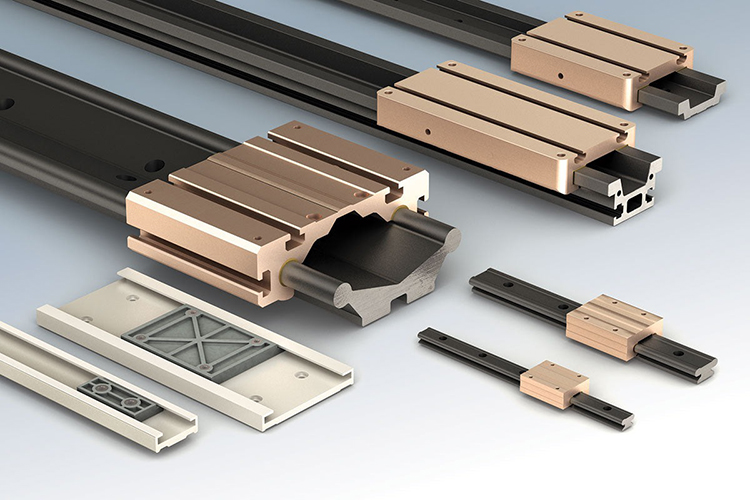

There are many types of linear guides, each with different designs, precision, and applications. Here are some of the most common types of guides and their characteristics:

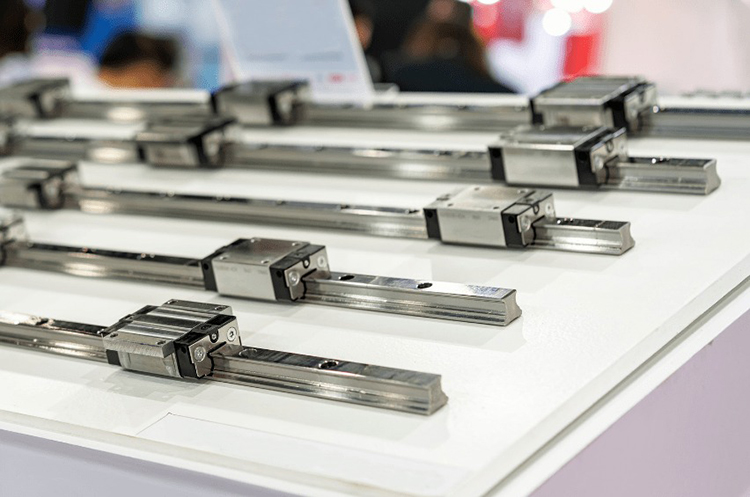

Linear Guides: Linear guides are used in applications that require high precision straight-line motion. They are commonly used in CNC machines, industrial robots, and automated production lines to ensure stable and accurate motion.

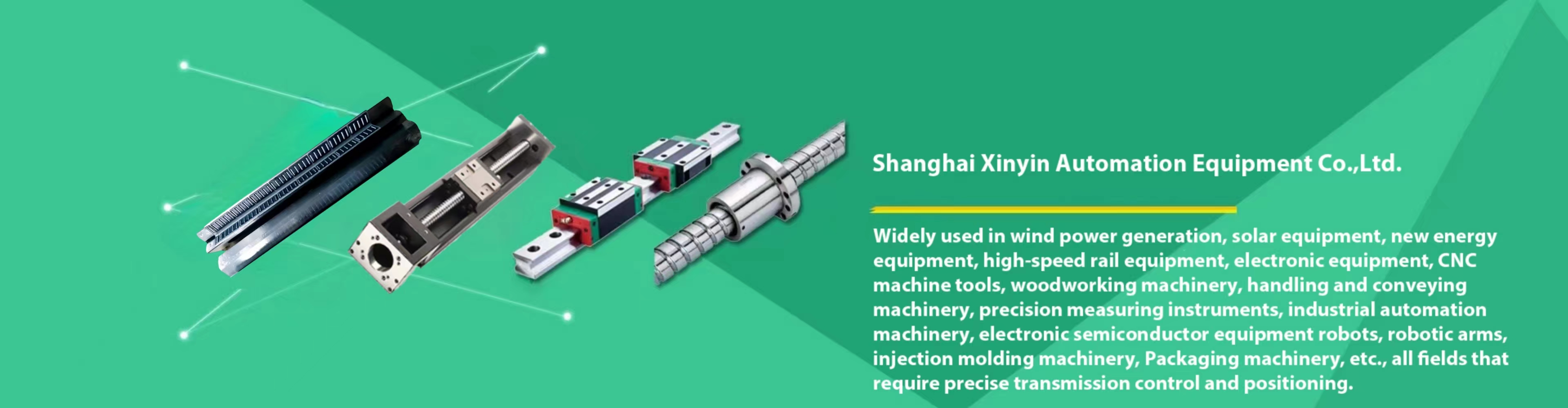

Ball Screws: These guides are mainly used for mechanical transmission and offer high transmission efficiency and accuracy, widely used in devices requiring precise positioning and motion.

Arc Guides: These are designed for applications that require curved or circular motion. They are often used in specific mechanical designs.

Crossed Roller Guides: These guides are suitable for applications requiring bi-directional motion and can provide precise control in multiple directions.

Ball Splines: These guides are ideal for carrying heavy loads, especially in high-speed, precise transmission systems.

Additionally, Shanghai Xinyin Automation Equipment Co., Ltd. offers specialized guides such as ceramic guides, high-temperature guides, and miniature roller guides, which cater to specific industries and working environments.

2. Main Application Areas of Linear Guides

Linear guides are essential in many industries. Here are some common fields where they are applied:

CNC Machines: Linear guides ensure the precise movement and positioning of components in CNC machines, improving processing accuracy and efficiency.

Automation Equipment: Whether it's robots, automated production lines, or conveyor systems, linear guides play a vital role in ensuring the stable and efficient operation of equipment.

Precision Measurement Instruments: In high-precision measurement tasks, guides provide very accurate linear motion to ensure the reliability of measurement results.

Electronics and Semiconductor Industry: In electronics manufacturing, linear guides are used for precise component handling and positioning, ensuring the efficiency and accuracy of production processes.

3. Factors Influencing Linear Guide Prices

The price of linear guides varies due to several factors, typically influenced by the following aspects:

Material and Manufacturing Process: The material (e.g., steel, stainless steel, ceramic) and the processing technique (e.g., surface hardening) directly impact the performance and cost. For instance, high-temperature or corrosion-resistant guides tend to be more expensive.

Precision Requirements: High-precision guides, used in applications requiring strict accuracy (such as in CNC machines or measurement instruments), are usually more expensive due to complex manufacturing processes.

Size and Load Capacity: Larger guides or those with higher load capacities typically cost more.

Brand and Quality: Well-known brands offering higher quality and better after-sales support tend to have higher prices.

4. How to Choose the Right Linear Guide

Selecting the right linear guide depends on your specific application requirements. Here are some factors to consider when choosing a guide:

Precision Requirements: If your equipment requires high precision (such as CNC machines or measurement instruments), it’s best to choose high-precision linear guides or ball screws.

Environmental Factors: In environments with high temperatures, humidity, or corrosive conditions, it is important to select guides made of materials that are resistant to these factors, such as high-temperature or corrosion-resistant guides.

Load Capacity: Choose guides based on the load requirements of your equipment to ensure long-term stability.

Size and Space: For equipment with limited space, miniature guides or specialized-shaped guides might be necessary to achieve precise motion in confined spaces.

5. Conclusion

Linear guides are a key component in precision machinery, and their performance has a significant impact on the overall functionality of the equipment. By understanding the different types of guides, their applications, and the factors that affect their prices, you can make an informed choice. Selecting the right type, material, precision, and load capacity of the guide is essential to ensuring the efficient and stable operation of your machinery.

Whether you are selecting guides for CNC machines, automation equipment, or electronics manufacturing, understanding these basic principles will help you make the best decision, improve operational efficiency, and reduce the risk of equipment failure.

- Groove-Type Linear Guides: Application Areas and Price Influencing Factors

- Linear Motion Modules: The Core Components for Enhanced Precision Transmission and Positioning

- Linear Guideways: A Key Component in Industrial Automation

- How to maintain plastic linear bearings?

- Linear Guide Modules: Precision Linear Motion Solutions

- What are the advantages of Shangyin heavy-duty ball screws

- How Much Does a Rail Cost Per Meter? A Guide to Rail Selection and Price Influencing Factors

- What are the characteristics of Shangyin linear guideway

- Choosing Affordable V-Guides: Advantages of Shanghai Xinyin Automation Equipment Co., Ltd.

- Custom Non-Standard Ball Screws: Key Solutions for Precision Linear Motion