Ring Rail Conveyor Systems: Pioneering Automation and Precision Transmission Technology

As industrial automation continues to evolve, ring rail conveyor systems have become an essential component in many production lines. Serving as a key piece of equipment for efficient, stable, and precise material handling, ring rail conveyors play a crucial role in a variety of industries. This article will introduce the basic principles, application areas, and the advantages of choosing a professional ring rail conveyor system manufacturer, providing valuable insights for businesses.

What is a Ring Rail Conveyor System?

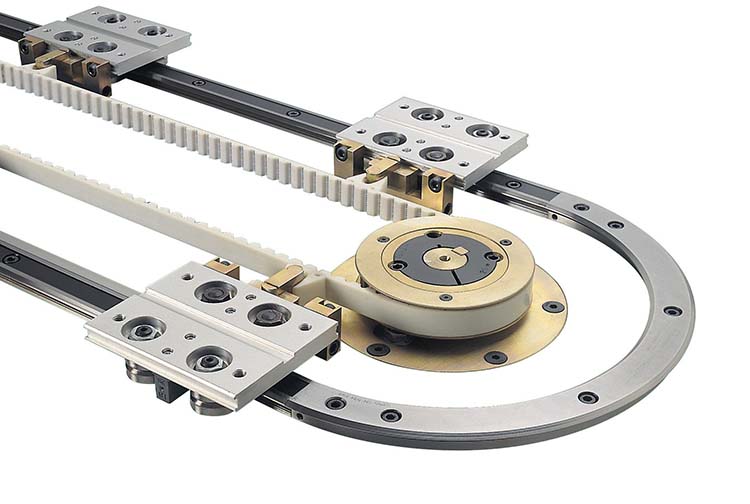

A ring rail conveyor system is designed to support the continuous and smooth movement of materials or components along a closed-loop track. With its unique design, it adapts to complex motion requirements and is widely used in industrial applications where precise positioning, transportation, and conveying are essential. By reducing friction and enhancing efficiency, the ring rail system provides robust technical support for automated production lines, robotics, and precision machining.

Compared to traditional linear guide systems, ring rail conveyors offer more flexibility, especially in applications requiring curved paths, making them ideal for certain specialized tasks.

How Does a Ring Rail Conveyor System Work?

The working principle of a ring rail conveyor system is based on the design of precision guide rails and an accurate drive mechanism. Key components usually include the rail body, rolling elements (such as ball bearings or rollers), a drive system, and a control system. Materials or components move smoothly along the track, with the drive system providing power and the rolling elements reducing friction, ensuring efficient operation.

This system is suitable for various automation devices and conveyor lines, providing high-speed, low-noise, and precise material handling.

Key Application Areas of Ring Rail Conveyor Systems

Ring rail conveyor systems are widely used in multiple industries, especially in environments where precise control and efficient conveying are required. Here are some of the most common application areas:

1. CNC Machines and Precision Machining

In CNC machinery, ring rail conveyor systems are used to provide stable motion paths and precise material handling. Whether in high-speed cutting, precision milling, or complex machining tasks, ring rail systems ensure high operational efficiency and machining accuracy.

2. Industrial Automation and Robotics

As industrial automation advances, ring rail conveyor systems are increasingly used in robotics. They support robots moving along a closed-loop track, carrying out tasks such as material handling and assembly. The ring rail system provides a stable path for robots, ensuring smooth operation on production lines.

3. Packaging and Logistics

In packaging and logistics industries, ring rail conveyor systems are often employed for automated material handling and sorting. They not only increase material transport efficiency but also ensure seamless transitions between different workstations, greatly enhancing production line automation and reducing labor costs.

4. Electronics Manufacturing and Semiconductors

Electronics and semiconductor production requires extremely high precision and clean environments. Ring rail conveyor systems are used to transport and assemble electronic components with precision, helping manufacturers improve productivity and reduce waste.

5. Medical Equipment and Precision Instruments

In medical equipment and precision measurement instruments, ring rail conveyor systems play a vital role in ensuring accuracy and stability. They provide precise support for medical robots, imaging devices, and laboratory automation equipment, ensuring high-quality production processes.

Why Choose a Professional Ring Rail Conveyor Manufacturer?

When selecting a ring rail conveyor system, businesses should consider not only the technical performance of the products but also the capabilities of the supplier. As a ring rail conveyor system manufacturer, a company can offer customized solutions to ensure that each ring rail system is perfectly suited to specific application needs. Here are several key advantages of choosing a professional manufacturer:

1. High Quality Assurance

Professional ring rail conveyor manufacturers usually have stringent production management systems, ensuring that their systems deliver high precision, reliability, and a long lifespan. This is crucial for industries that require extremely high accuracy, such as CNC machining and electronics manufacturing.

2. Customized Design Services

Different industries and applications have specific requirements for ring rail conveyor systems. A skilled manufacturer can offer customized rail system designs that address unique production challenges, providing tailor-made solutions to meet specific needs.

3. Technical Support and After-Sales Service

Reputable manufacturers often provide comprehensive technical support and after-sales services to ensure the long-term stability of the equipment once it's in operation. Clients can receive professional assistance during installation, commissioning, and maintenance, minimizing the risk of production disruptions.

4. Ongoing Technological Innovation

Leading ring rail conveyor system manufacturers continuously focus on technological advancements, using the latest materials and techniques to enhance product performance. For example, the use of high-temperature-resistant and corrosion-resistant materials can allow the ring rail system to operate in harsher environments, meeting the needs of specialized industries.

Shanghai Xinyin Automation Equipment Co., Ltd.: A Trusted Ring Rail Conveyor Manufacturer

As a leading ring rail conveyor system manufacturer, Shanghai Xinyin Automation Equipment Co., Ltd. is committed to providing high-quality guide products and customized solutions for various industrial automation systems. The company’s products include linear guide rails, ball screws, curved rails, and more, widely used in CNC machinery, robotics, packaging machines, and logistics systems. With years of technological expertise and industry experience, Shanghai Xinyin Automation Equipment Co., Ltd. holds a strong position in the ring rail conveyor system market.

Whether for standard products or customized requirements, Shanghai Xinyin Automation Equipment Co., Ltd. can deliver high-efficiency, precise guide systems to help customers achieve automation and improve operational efficiency. Partnering with Shanghai Xinyin Automation Equipment Co., Ltd. offers you quality products, professional technical support, and comprehensive after-sales service.

Conclusion

Ring rail conveyor systems are a core component of industrial automation, used in a wide range of industries, including CNC machining, robotics, logistics systems, and medical equipment. Choosing a reliable ring rail conveyor manufacturer can provide businesses with efficient, stable, and precise production systems, boosting productivity and reducing operational costs.

If your business is looking for high-quality ring rail systems, consider collaborating with a professional manufacturer to customize solutions tailored to your specific needs. Shanghai Xinyin Automation Equipment Co., Ltd. offers comprehensive technical support and services to help you maintain a competitive edge in the market.

- What are the characteristics of Shangyin linear guideway

- How to identify the authenticity of ball screws

- Customized Ball Screws: Meeting the Needs of Precision Linear Transmission

- Linear Guide Modules: Precision Linear Motion Solutions

- How to choose the type of ball

- Custom Non-Standard Guide Rails: The Key to Enhancing Precision Motion and Positioning in Industrial Applications

- Precision ground ball screw

- Ball Screw Customization According to Drawing – The Key to Enhancing Precision Transmission Efficiency

- Arc Rail Drive Methods and Application Guide

- Linear Motion Modules in Modern Industry: Applications and Importance