Customized Machine Tool Guide Price and Its Application Areas

In modern industrial manufacturing, precision machine tool guides are essential for ensuring efficient and accurate operation of equipment. Especially in fields such as CNC machines, woodworking machinery, and automation systems, selecting the right guide system not only improves work efficiency but also extends the lifespan of the equipment. Shanghai Xinyin Automation Equipment Co., Ltd., a leading supplier of guide rails and precision transmission components, offers a variety of customized machine tool guides to meet the needs of different industries. This article will explore the price range of customized machine tool guides and their applications in various fields.

1. Factors Affecting the Price of Customized Machine Tool Guides

The price of customized machine tool guides is influenced by various factors, including material, size, precision requirements, manufacturing process, brand, and order quantity. Generally, standard linear guides and ball screws are more affordable, while guides with higher precision and load-bearing capacities tend to be more expensive.

Material: Common guide materials include steel, cast iron, stainless steel, and special alloy materials. For example, guides made from high-temperature alloys can withstand higher operating temperatures and are generally more expensive than those made from conventional materials.

Precision and Load Capacity: The higher the precision and load-bearing capacity required, the more expensive the guide will be. For example, precision machine tools require micrometer-level precision, which drives up the price.

Customization Requirements: Customized guides, such as special-shaped guides or those designed for unique working environments (e.g., ceramic guides for high temperatures or corrosive environments), typically involve more complex manufacturing processes and therefore come at a higher price.

Quantity: Bulk orders usually come with significant price discounts, whereas small custom orders may result in higher unit prices.

2. Products Offered by Shanghai Xinyin Automation Equipment Co., Ltd.

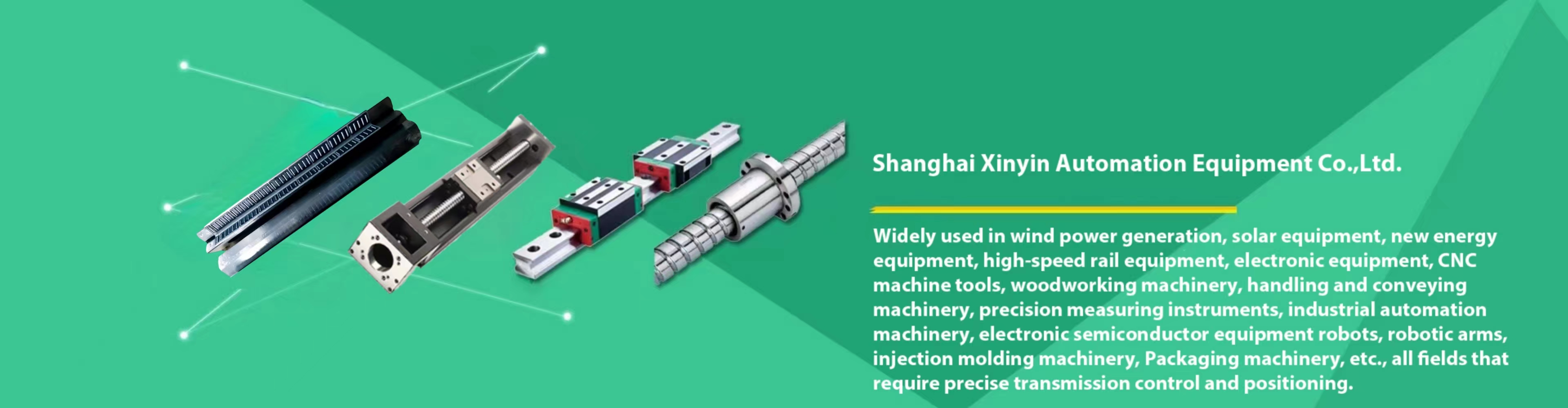

Shanghai Xinyin Automation Equipment Co., Ltd. offers a wide range of high-quality machine tool guides and precision transmission components, suitable for various industrial applications. Below are some of the key products and their applications:

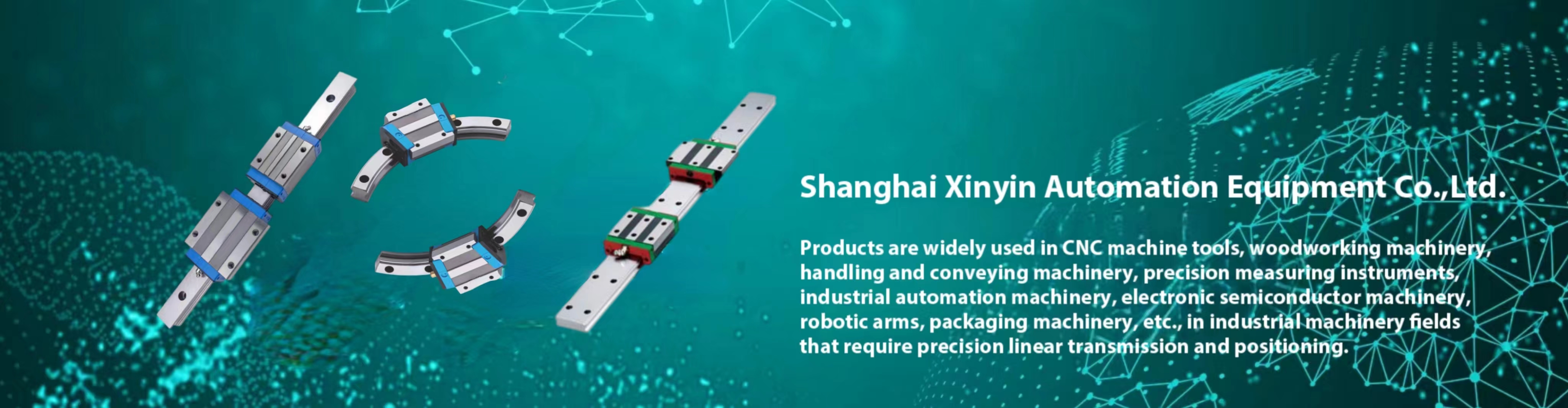

Linear Guides: Linear guides are among the most common types of machine tool guides and are widely used in CNC machines, woodworking machinery, and other fields that require precise linear motion.

Ball Screws: Ball screws are used to transmit motion and power, known for their high precision and efficiency. They are widely used in precision machinery and automation systems.

Arc Guides and Cross Guides: These guides are used in machines with special motion paths, such as machining centers and robotic arms.

Ball Splines and Guide Clamps: These components help improve system stability and are commonly used in industrial automation and precision equipment.

Ceramic Guides and High-Temperature Guides: These are suitable for high-temperature or highly corrosive environments, offering excellent durability.

Micro Guides and Special-Shaped Screws: These are designed for small-scale equipment or customized applications, meeting the needs of precision control and miniaturization.

3. Applications of Machine Tool Guides in Various Industries

Machine tool guides are widely used across many industries. Below are some specific examples of their applications:

CNC Machines: CNC machines require highly precise positioning and stability, making linear guides and ball screws indispensable components. With a precise guide system, the machine can perform fine cutting, milling, and other processes.

Woodworking Machinery: Woodworking machinery requires guide systems to ensure the accuracy of wood processing. In particular, linear and arc guides can improve the consistency and quality of products in furniture manufacturing.

Automation Systems: In robotics and automated production lines, machine tool guides support and drive the precise motion of various automated equipment. Particularly in electronic semiconductor and precision measurement instruments, guide systems require very high precision and reliability.

Packaging Machinery and Conveying Systems: Automatic packaging machinery and conveyor systems need precise positioning and stable operation, and machine tool guides provide the necessary linear motion control.

Electronics and Semiconductor Equipment: Since electronic components require extremely high precision and stability, precision machinery used in electronics often employs high-precision ball screws, linear guides, and micro guides to achieve efficient and accurate control.

4. Key Factors to Consider When Choosing Machine Tool Guides

When selecting machine tool guides, businesses need to choose the right type of guide based on their specific application requirements. Below are some important factors to consider when making a selection:

Working Environment: Factors such as temperature, humidity, and corrosiveness should be considered. If the equipment operates in a special environment (e.g., high-temperature or corrosive conditions), guides made of high-temperature or corrosion-resistant materials are required.

Load Capacity: Different machine tools have different load requirements, so the guide should be selected based on the load capacity needed.

Motion Precision: For equipment that requires precise control or high-precision motion (e.g., precision instruments, medical devices), high-precision ball screws and linear guides are necessary.

Maintenance and Care: Some specialized guides, such as ball splines or ceramic guides, may require more complex maintenance, while standard linear guides are easier to maintain.

5. Conclusion

The price of customized machine tool guides varies depending on multiple factors. However, for equipment that demands high precision and load-bearing capabilities, investing in high-quality guides is worth it. Shanghai Xinyin Automation Equipment Co., Ltd., with its rich experience and diverse product offerings, can provide cost-effective guide solutions to meet the needs of various industries.

Whether for CNC machines, automation systems, woodworking machinery, or packaging equipment, Xinyin Automation’s guide products offer precise and stable motion control, helping to improve production efficiency and product quality. If you have custom requirements, feel free to contact Shanghai Xinyin Automation Equipment Co., Ltd. for more professional consultations and quotes.

- Linear Motion Modules in Modern Industry: Applications and Importance

- Custom Non-Standard Guide Rails: The Key to Enhancing Precision Motion and Positioning in Industrial Applications

- Linear Guide Prices and Selection Guide: How to Choose the Right Guide for Your Needs

- Linear Guideways: A Key Component in Industrial Automation

- What are the advantages of ball screw linear modules

- How to maintain plastic linear bearings?

- How to identify the authenticity of ball screws

- Ball Screw Customization According to Drawing – The Key to Enhancing Precision Transmission Efficiency

- To ensure the normal operation of the silver guide rail, daily lubrication is very important! ! !

- Ring Rail Conveyor Systems: Pioneering Automation and Precision Transmission Technology