How to identify the authenticity of ball screws

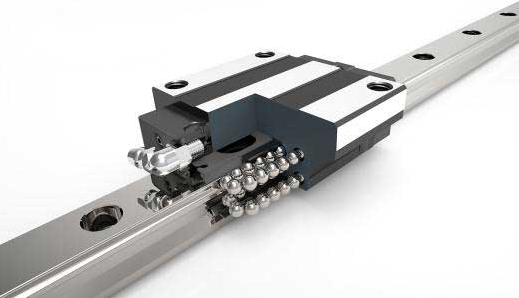

Buying fake ball screws will damage the machine and make it impossible to start the machine. This is a big loss for the company. How do you identify a genuine or fake ball screw? Just judge whether the ball screw is correct or not - just the equipment is different, you will see a pair of ball screws. When planning to measure Rockwell hardness and ball screw specifications, look at the size and space of the equipment.

Maximum HRC60. The load on the screw must also be considered. (Can be compared with the drawings) Regarding the drawings, Leiyan Precision Transmission Equipment has various drawings, please call to request. Online introduction method: Use a dial indicator to test both ends and center respectively on a horizontal platform (if the beat of 300 is 0.02), the accuracy is in C3, which means there is no problem with the screws, you should check whether the coaxiality of the machine is not correct Adjustment.

Otherwise, it's a screw issue! Also ask what brand of screws you bought. C3 should be grinding grade. If you don’t buy cold-rolled screws, cold-rolled ball screws are not that high-precision. Note: If there is no problem with accuracy, the runout of the screw can be detected. Currently, there is no better way to detect it.

The above detection method is the most basic and most effective method. As for how to choose screws, you should first determine the accuracy. After setup, the load must be determined. Motor speed is also walking distance. After fixing the screw, determine the diameter of the screw and then determine the pre-tightening force. The preload of the grinding table should be P2 or P3, that is, no gap for light load or medium load, etc., which cannot be tested with instruments.

- What are the advantages of Shangyin heavy-duty ball screws

- Custom Non-Standard Ball Screws: Key Solutions for Precision Linear Motion

- Customized Ball Screws: Meeting the Needs of Precision Linear Transmission

- Arc Rail Price and Application Field Analysis

- How to choose the type of ball

- Linear Guide Modules: Precision Linear Motion Solutions

- To ensure the normal operation of the silver guide rail, daily lubrication is very important! ! !

- Custom Non-Standard Guide Rails: The Key to Enhancing Precision Motion and Positioning in Industrial Applications

- What are the characteristics of Shangyin linear guideway

- Arc Rail Drive Methods and Application Guide